The Benefits of 3D Printing in Manufacturing

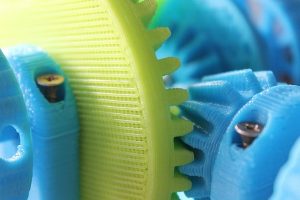

The Manufacturing industry is continually looking at new and innovative ways of working, and in the past few years, 3D printing has taken over. Improvements in 3D printing technology, equipment, and materials have led to a reduction in costs, making it a more practical option for general manufacturing use. 3D printing offers manufacturers several exciting and unique benefits.

Below are some of the benefits of 3D printing in the manufacturing industry:

Reduced Costs

Traditional manufacturing methods are known to be expensive. 3D printing process, on the other hand, makes the creation of products cheaper. 3D printing eliminates the need for having many people working on several machines. 3D printing is an automated process and only requires one operator to start the machine. This significantly reduces the manufacturing costs as there is no need for skilled operators.

Traditional manufacturing methods are known to be expensive. 3D printing process, on the other hand, makes the creation of products cheaper. 3D printing eliminates the need for having many people working on several machines. 3D printing is an automated process and only requires one operator to start the machine. This significantly reduces the manufacturing costs as there is no need for skilled operators.

Improves the Marketing Times

3D printing makes it possible to develop ideas quickly. At times, it is possible to design and print 3D concepts within the same day, which is faster than conventional methods when it comes to large-scale manufacturing. This helps companies to minimise their manufacturing times from months to days in a bid to keep them ahead of their competitors.

Allows the Chance to Build and Grow

Businesses that take up 3D manufacturing can enjoy continued growth and development through the production of items that have been designed from their imagination. As far as 3D manufacturing is concerned, there are no limits as products can be virtually created and then printed within a short time. This means that a product can transform from an idea to a concept, and a finished part within a short time.

Businesses that take up 3D manufacturing can enjoy continued growth and development through the production of items that have been designed from their imagination. As far as 3D manufacturing is concerned, there are no limits as products can be virtually created and then printed within a short time. This means that a product can transform from an idea to a concept, and a finished part within a short time.

Minimises Storage Space

The majority of industries require businesses to store the products and parts that they need or sell. This means that a lot of storage space is needed to store products that can sit around for long. With 3D, products are made as they are sold.